WHY GRINDING MACHINE BHM CNC?

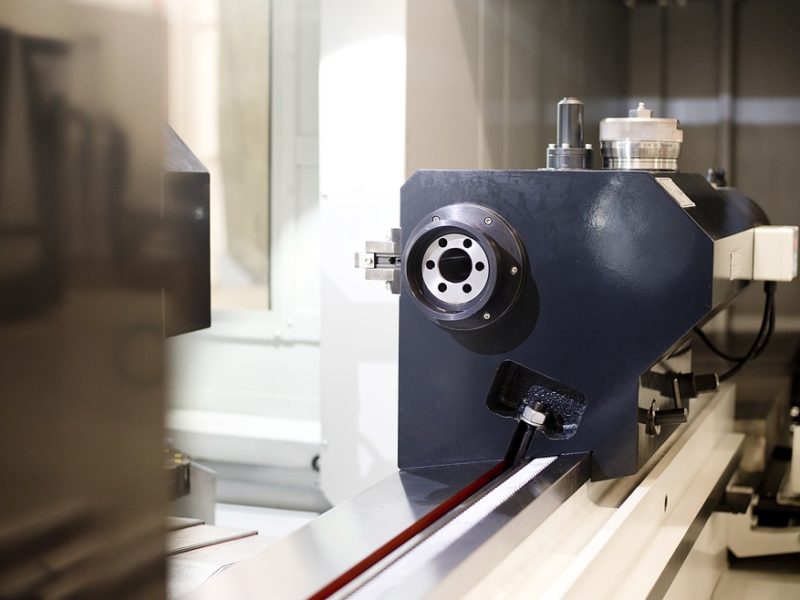

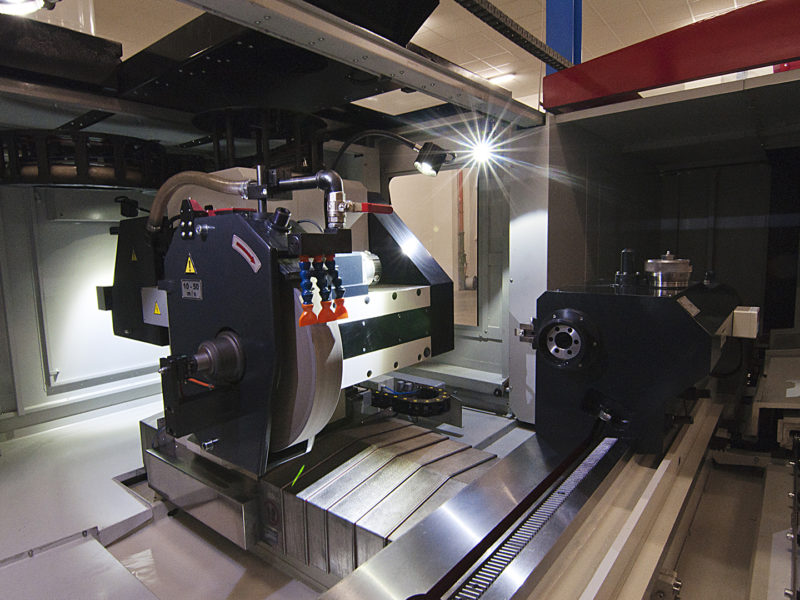

The BHM universal grinding machine is designed for external and internal grinding of workpieces clamped between the centers or clamped in the chuck. The feed-in of the grinding wheel head and the table are realized by servomotors and ball screws. The BHM grinder is a very stable and precise machine that can be used in series production as well as in single-part production for workpieces up to 1 500 kg.

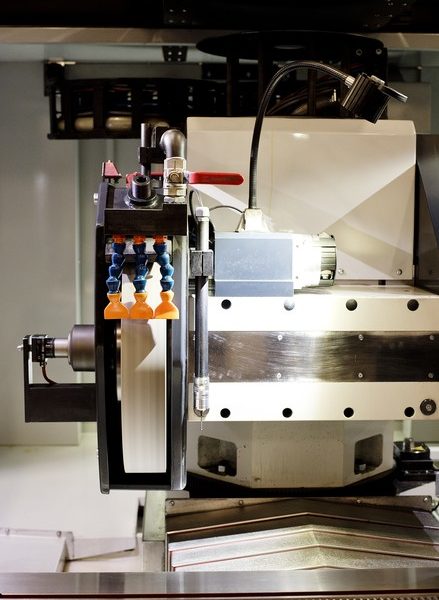

The machine grinds in working accuracy IT 4 and can be equipped with modern design features, as for example rolling bearing of the grinding spindle or hand scraping guideways with Teflon pads for minimal adhesion (stick-slip effect). In addition, the machine can be upgraded with an in-process gauge, axial probe, automatic (electric) steady rests, CNC rotary dresser, electric spindles, Z-axis encoder, etc.

The machine can be installed with SINUMERIK 828D sl, SINUMERIK 840D sl, SINUMERIK ONE or FANUC control system.

The grinder is designed primarily for numerically controlled grinding of external cylindrical surfaces of various diameters and their neighbouring faces and radius. So called sweep cones may be ground by interpolation between axis X and Z. Grinding wheel head is mutually rotational. It enables vertical plunge-cut grinding using spindle swivel. This method may be particularly used for grinding steep cones and simultaneous grinding of cylindrical and face surfaces of workpieces. A folding device with a separate spindle is used for internal grinding.

In the special version, the machine is equipped with a C axis for precise positioning and grinding of non-circular shapes, a stiffer clamping work head or a polishing device for high surface quality. These superior features make the machine the most versatile and efficient solution on the grinding machines market.

| Swing diameter | mm in | 500 (600) 19,7 (23,6) |

| Distance between centers | mm in | 1000 / 1500 / 2000 / 3000 39,4 / 59 / 78,7 / 118,1 |

| Max. weight of workpiece | kg lb | 1500 3307 |

| Wheel head swivel | ° | +15 / -180 (manual) |

| Max. number of used tools | pcs | 1+1 |

| Grinding wheel peripheral speed | m.s-1 | 10-50 |

| Grinding wheel dimensions (dia. x width x bore) | mm in | Ø 500 x 80 x Ø 203 Ø 19,7 x 3,1 x Ø 8 |

| Wheel head motor power | kW hp | 11 14,9 |